Automate Preventative Maintenance Tasks in Dynamics 365 Field Service for Better Results

You can change how you handle preventative maintenance by using automation in Microsoft Dynamics 365 Field Service. Power Automate helps make your work easier and keeps maintenance plans current. When you use these tools, your work gets better and your equipment works longer. The numbers show real improvements:

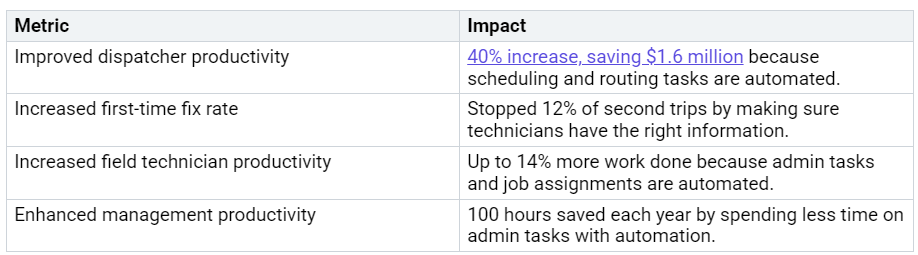

Preventative Maintenance Optimization gives…