Business Central manufacturing made simple for everyone

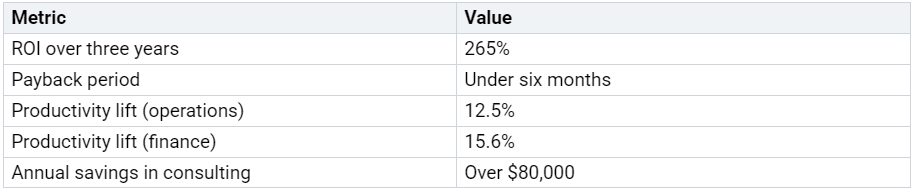

You do not have to be a tech expert to use Dynamics 365 Business Central for manufacturing. Business Central gives you easy tools and clear steps. This helps small and medium businesses manage every process. Many people see results quickly. There is a 265% ROI in three years and payback in less than six months:

You get real-time insights and better effic…