Mastering Production Plans with Effective Routing and Resource Allocation

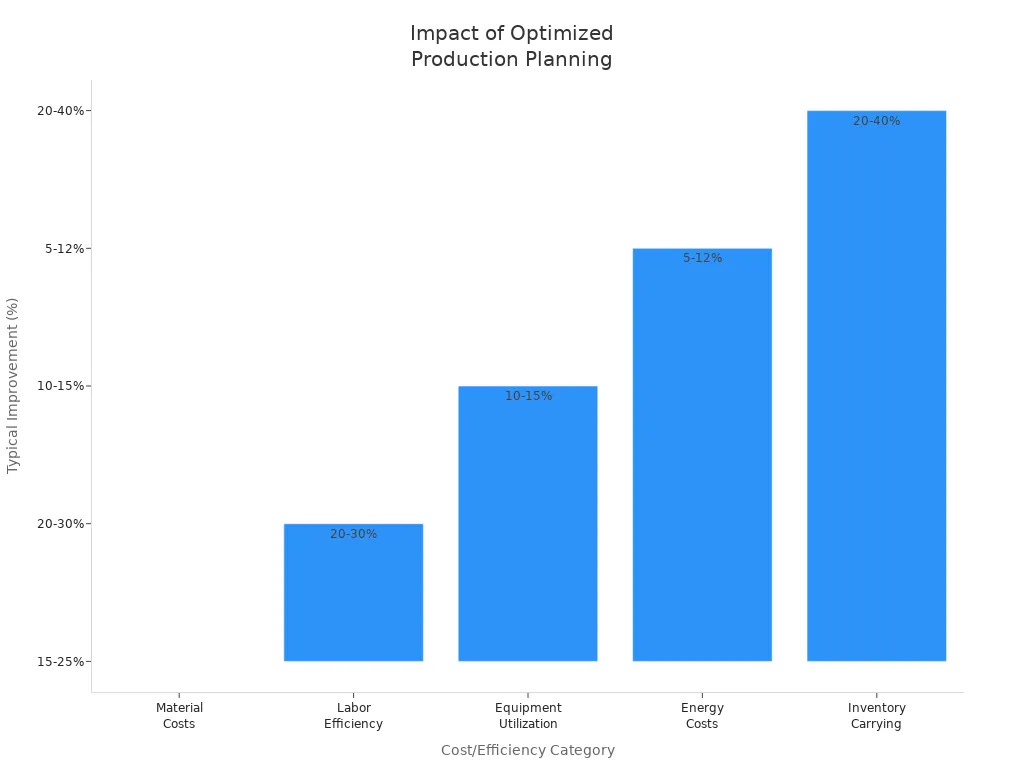

Optimizing your production plans can help you save money and time. When you use good routing and resource allocation, you get better results. For example, companies can cut material costs by 15-25%. They can also make labor more efficient by 20-30%.

A production plan tells you what to make and when to make it. It also shows which resources you need. Rout…