Effective inventory management is very important in today’s business world. 62.3% of warehouse workers say inventory control is their biggest problem. Businesses need to focus on being accurate and efficient. Business Central has strong tools to help with these problems. For example, it gives real-time updates and automated processes. These features improve inventory accuracy more than manual systems. By making operations smoother, you can change how you manage inventory. This will help your business perform better.

Key Takeaways

Good inventory management is very important for business success. Use Business Central’s real-time updates to make things more accurate and efficient.

Fix stock mistakes by training workers and using automated systems. This cuts down on errors and makes customers happier.

Use inventory tracking methods like Just-In-Time and ABC Analysis. These ways help keep stock levels right and lower costs.

Use Business Central’s features to connect with other systems. This makes operations smoother and improves inventory management.

Regular checks and clear rules make sure everything is correct. Keep your inventory records reliable to keep stakeholder trust.

Inventory Challenges

Stock Inaccuracies

Stock inaccuracies create big problems in inventory management. These mistakes often happen for many reasons, such as:

Human Errors: Workers sometimes enter wrong amounts or label items incorrectly when picking orders.

Poor Training: Employees who don’t know the rules can make mistakes.

Systemic Errors: Problems in inventory software or old systems may not process data right.

Stock Damage: Items that get damaged during handling or storage often aren’t recorded, messing up inventory counts.

Supply Chain Disruptions: Delays or lost items during shipping can cause mistakes.

Inefficient Cycle Counting: If audits aren’t done regularly, errors can build up without anyone noticing.

Theft and Fraud: Both inside and outside theft lead to less inventory.

Obsolete Inventory: Old items make stock levels look higher than they are.

Inadequate Technology: Companies using old software are more likely to make mistakes.

Reliance on Outdated Technology: Many businesses still use old systems that can’t handle today’s inventory needs.

These inaccuracies can hurt your business badly. For example, not having enough stock means lost sales, while too much stock ties up money and may need discounts, hurting profits. Also, fixing mistakes costs extra money, like paying workers to recount and speeding up shipping to fix stockouts.

Customer satisfaction depends on inventory accuracy. When customers can’t find what they want because of stockouts, it hurts their trust and loyalty. Keeping accurate inventory records is key to filling orders correctly and on time, which boosts customer satisfaction.

Fragmented Item Data

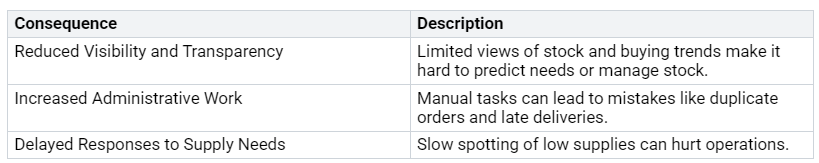

Fragmented item data makes inventory management even harder. A huge 90% of all data created in the last five years is unstructured, making it tough for companies to manage well. This fragmentation causes several problems:

When item data is fragmented, you have more administrative work and slower responses to supply needs. This can lead to bad decisions and missed chances.

Solutions with Business Central

Item Setup and Definitions

Business Central makes item management easier with its clear item setup process. You can create a central item list that has important details like categories, attributes, and dimensions. This standard way of organizing items cuts down on mistakes and makes it simpler to keep accurate inventory records.

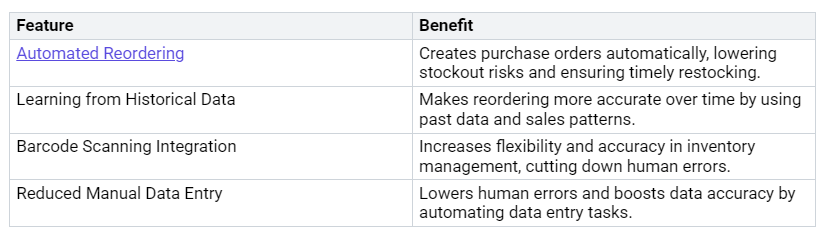

Here are some important features that help you track your inventory:

Real-Time Availability by Location: You get instant updates on how much stock you have, what is reserved, and what you expect to have after each transaction. This helps you promise accurate stock levels and avoid mistakes.

Automated Replenishment Policies: Business Central has four built-in options to automatically calculate and create orders. This lowers manual errors and makes inventory management smoother.

AI-Driven Demand Forecasting: The system uses Azure AI to guess future sales and suggest when to reorder. This helps you avoid running out of stock and keeps your inventory at the right level.

Compared to other ERP solutions, Business Central is easy to set up. You can adjust warehousing processes to fit your business’s needs. This flexibility helps growing businesses change without needing a lot of training. Other systems might need expert help to set up, which can make learning harder.

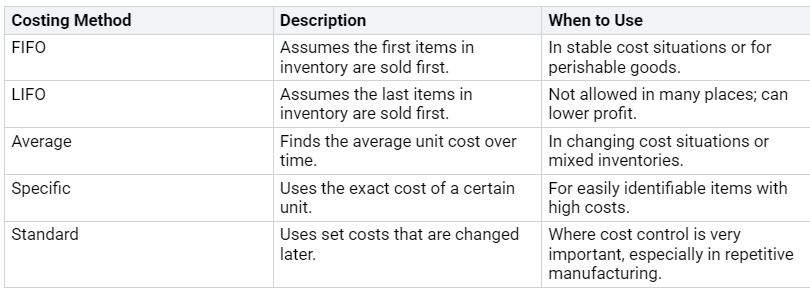

Costing and Valuation

Getting costing and valuation right is very important for good inventory management. Business Central supports different costing methods, like FIFO, LIFO, Average, Specific, and Standard. Each method affects how you figure out and report inventory costs, which can change your financial statements and taxes.

The formula for figuring out inventory costs is:

Ending inventory = beginning inventory + net purchases – cost of goods sold

Business Central uses the Cost Amount (Actual) field of value entries to calculate this, sorted by entry type. The inventory value comes from adding positive and negative value entries based on their posting dates.

Here’s a quick look at the costing methods that Business Central supports:

Getting inventory valuation right helps you make smart decisions. You get insights based on facts, not guesses. This openness builds trust with stakeholders and helps you find ways to save money and use resources better.

Effective Inventory Management Strategies

To manage inventory well, you need to use different strategies. These strategies help make your work more accurate and efficient. Here are some steps you can take to improve how you manage inventory.

Inventory Tracking Techniques

You can use several ways to track inventory and make your operations better. Here are some of the best methods:

Just-In-Time (JIT) Inventory: This method lowers holding costs by making sure materials arrive when needed.

ABC Analysis: Sort inventory into three groups to focus on high-value items.

Cross-Docking: Cut down storage time by moving incoming shipments straight to outgoing ones.

Cycle Counting: Count a part of your inventory regularly to keep it accurate without stopping work.

Barcode and RFID Technology: Use tags to automate tracking and improve accuracy.

Optimizing Warehouse Layout: Arrange inventory based on demand to boost efficiency.

Using these techniques can greatly improve your inventory management. For example, barcode and RFID technology can automate data collection. This reduces mistakes and leads to better inventory records and decisions.

Warehouse Operations Optimization

Making warehouse operations better is key for good inventory management. Business Central has many tools that help streamline your warehouse work. Here are important steps to improve warehouse management:

Inventory Management: Keep track of inventory levels and movements in real-time for better choices.

Order Processing: Make workflows smoother for creating, picking, packing, and shipping orders.

Warehouse Layout and Bin Management: Design and manage warehouse spaces for better use of space.

Receiving and Put-Away: Handle incoming shipments and put-away tasks efficiently.

Pick and Pack: Use methods like wave picking and zone picking for better accuracy.

Automated Data-Capture: Use barcode scanners and other tools for quick data collection.

By using these tools, you can improve your warehouse operations. For instance, Business Central helps you set up detailed location plans, manage inventory, and streamline how goods move from receiving to storage. This can greatly lower mistakes and boost efficiency.

Tip: Regular training and support are key to getting the most from these strategies. Make sure your team knows how to use Business Central well. Ongoing training on updates helps your team stay flexible in a changing business world.

Best Practices for Success

Compliance and Audit Readiness

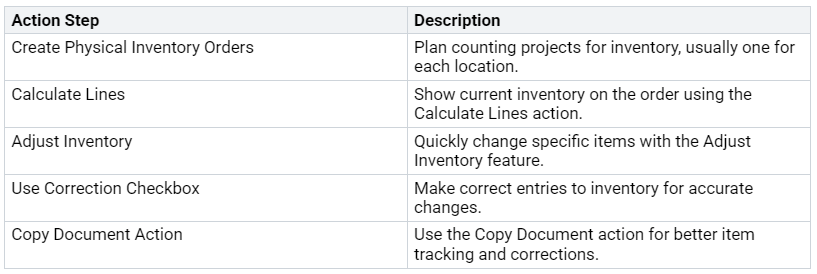

Keeping compliance and audit readiness is very important for good inventory management. You should do regular audits to check accuracy and openness in your inventory records. This helps you find mistakes early and keep trust with stakeholders. Here are some best practices to improve compliance:

Establish Clear Policies: Write down and explain inventory management rules. Make sure all workers know their roles in keeping compliance.

Utilize Audit Trails: Use Business Central’s audit trails to see changes in inventory. This feature shows a clear history of adjustments, transfers, and costing changes.

Conduct Regular Reviews: Plan regular checks of inventory metrics. This helps you stay updated on stock levels and compliance status.

Tip: Real-time inventory visibility helps stop stockouts and overstocking. Automated replenishment uses past sales data and demand forecasting to improve restocking.

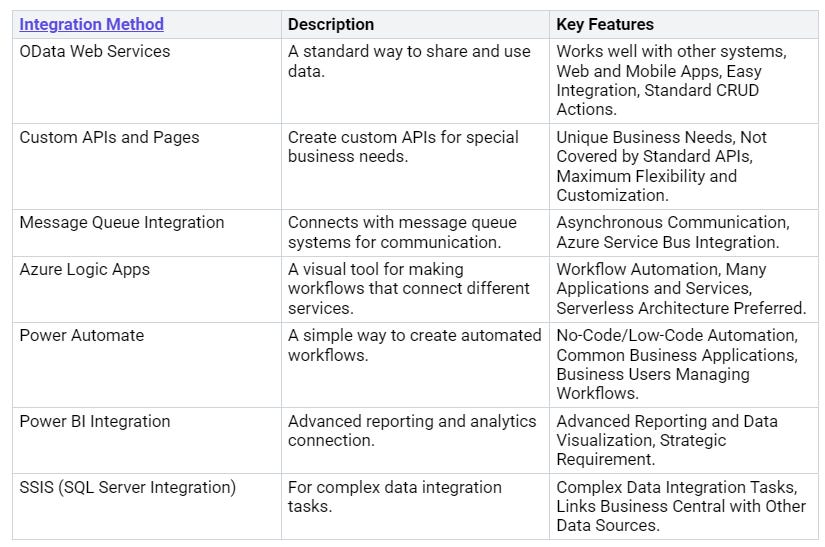

Integration and Extensibility

Connecting Business Central with other systems improves your inventory management skills. You can link with different business systems to make operations smoother. Here are some ways to integrate in Business Central:

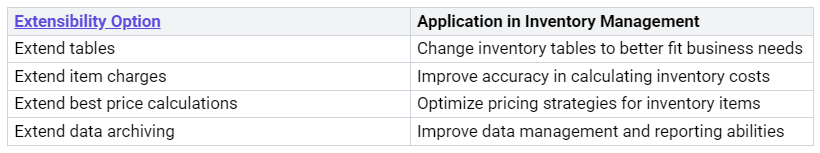

Extensibility in Business Central also boosts your inventory management skills. You can change different parts to better fit your business needs. Here’s how:

By using these integration and extensibility options, you can build a more efficient and quick inventory management system. This flexibility helps you respond fast to market changes and improve overall operational efficiency.

Improving your inventory management with Business Central can really help your business. For example, Silver Spirit got real-time updates on stock levels. This helped them avoid running out of items or having too much. VK Industries cut their data entry work by half and reduced manual calculations by 75%. This made their costs clearer and more accurate.

To start making your inventory better, try these steps:

By following these steps, you can improve your inventory management and get better results for your business.

FAQ

What does Business Central do for inventory management?

Business Central keeps all your inventory data in one place. It gives you updates right away, automates tasks, and tracks items accurately. This helps you manage stock levels better and make fewer mistakes.

How can I make my inventory more accurate?

You can make it more accurate by doing regular cycle counts, using barcode technology, and training your staff. Business Central’s automated restocking also helps keep the right amount of stock.

What are the advantages of using AI in inventory management?

AI helps with predicting demand and automating orders. It looks at past data to guess future needs, which helps you avoid running out of stock and keeps your inventory at the right level.

How does Business Central help with compliance?

Business Central provides audit trails and real-time views of inventory changes. Regular audits and clear rules help you follow regulations and keep trust with stakeholders.

Can I connect Business Central with other systems?

Yes, Business Central can connect with many systems using APIs and tools like Power Automate. This connection makes operations smoother and improves your inventory management skills.