In today’s busy business world, automated inventory replenishment is very important. It helps make operations run better. You can easily spot problems with real-time inventory checks. This smart management helps you fill orders faster and makes customers happier. Business Central’s automation makes inventory management easier. It uses AI systems to keep stock levels just right. These systems cut down on manual work. This lowers the chances of running out of stock or having too much. By using these inventory management tools, you can improve customer service and save on inventory costs.

Key Takeaways

Automated inventory replenishment makes work easier. It cuts down on manual tasks and keeps stock levels just right.

Demand forecasting in Business Central uses smart math to guess what inventory is needed. This helps keep customers happy and saves money.

Reorder point calculations help keep the right amount of stock. This stops running out of items or having too much, which lowers shipping costs.

Setting up automated replenishment means adjusting templates and checking settings. This helps everything run smoothly and keeps inventory accurate.

Inventory automation saves a lot of money and makes things more accurate. This leads to better customer experiences and smoother business operations.

Business Central Features

Demand Forecasting

Demand forecasting is an important part of Business Central. It helps you guess what inventory you will need in the future. This feature lets you make smart choices using past data and market trends. Business Central uses advanced algorithms like Auto-ARIMA, ETS, Prophet, and XGBoost to make your forecasts better. These algorithms look at different data patterns. This way, you have the right stock levels when you need them.

Benefits of Demand Forecasting:

Lowers the chance of running out of stock or having too much.

Increases customer happiness by keeping products in stock.

Cuts costs by managing inventory levels well.

Unlike many other ERP systems that need manual uploads, Business Central does demand forecasting automatically. This automation reduces mistakes and gives you updates based on market changes. So, you can be sure your inventory choices are based on data and are timely.

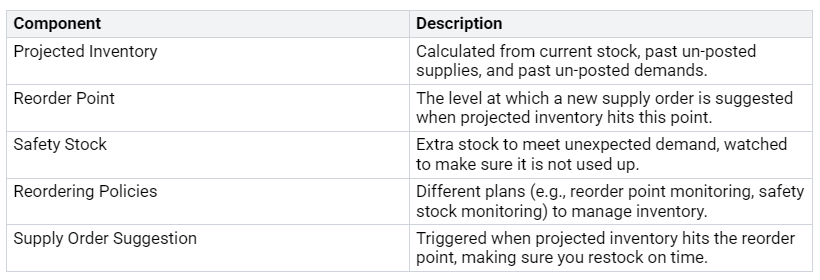

Reorder Point Calculation

Reorder point calculation is another key feature in Business Central. This process helps you keep the right stock levels. It suggests new orders when your inventory hits a set limit. The system figures out reorder points based on expected demand during the item’s lead time. It checks for current supply orders and only suggests new ones when needed.

Using good replenishment rules helps you avoid running out of stock. Businesses that use reorder points often see fewer stockouts and overstocking. This means lower shipping costs and better inventory predictions. Keeping an eye on reorder points makes sure products are available for customers, which improves overall satisfaction.

By using these inventory management features, you can make your operations smoother and keep track of stock levels better. Automated replenishment processes save time and improve accuracy compared to doing it by hand.

Automated Replenishment Setup

Setting up automated replenishment in Business Central is very important. It helps keep your inventory levels just right. This process has several steps to make sure your inventory system works well. Here’s how to set up automated replenishment the right way:

Initial Configuration

Configure a Replenishment Template: First, define how to create work. This means making a unique Template ID, choosing the Replenishment Type, and setting important details.

Define a Work Template: Next, list the steps for making replenishment orders. Include things like Work Order Type and Sequence Number to make it easier.

Create Location Directives: Decide where items are picked and put during replenishment. Set up ‘Pick’ and ‘Put’ lines to help your warehouse workers.

Configure Mobile Device Menu Items: Let your workers do tasks easily with mobile devices. Make a menu item in Work mode for quick access to replenishment tasks.

Run the Replenishment Job: Finally, create replenishment work using the templates and directives you set up. This step keeps your inventory levels just right based on what you need.

Tip: Watch out for common problems during the setup. You might face issues with stockkeeping units and replenishment systems. Some setups may need to change based on the type of replenishment, like Purchase Orders or Production Orders.

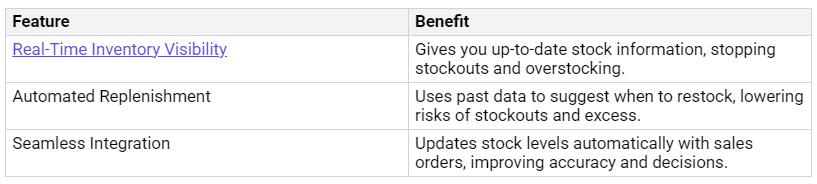

Monitoring Settings

Monitoring settings in Business Central are very important for keeping inventory levels right. Good inventory management helps you meet customer needs while avoiding too much or too little stock. Business Central gives you real-time visibility, automates replenishment, and uses advanced analytics for better demand forecasting. These features help lower carrying costs and stockouts, making your operations run better.

By using these monitoring settings, you can make sure your inventory levels match demand forecasts. This smart approach lets you change your replenishment plans when needed, leading to happier customers and lower costs.

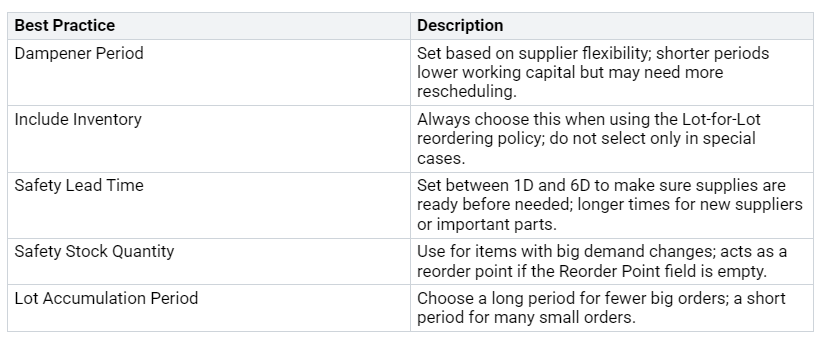

Defining inventory policies is also very important. Setting clear replenishment rules helps you manage stock levels well. For example, think about these best practices when making your inventory policies:

By following these tips, you can build a strong automated replenishment system that improves your inventory management skills.

Benefits of Inventory Automation

Automated inventory processes have many great benefits for your business. You can save money and improve accuracy when you use these systems.

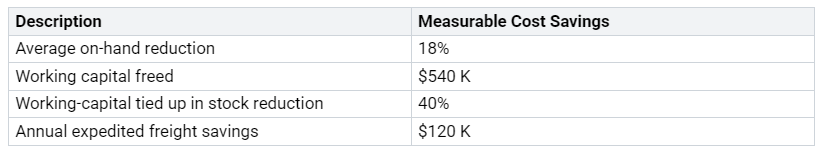

Cost Savings

Using automated inventory replenishment can help you save a lot of money. Many businesses have noticed big savings after they started using automation. For example, companies have seen an average on-hand reduction of 18%. This means they freed up $540,000 in working capital. They also reduced the working capital tied up in stock by 40%. This saved them $120,000 each year on fast shipping costs.

You also save on labor costs. Keeping track of inventory accurately stops overstocking. This lowers storage costs. Better inventory processes save time and boost productivity. Automated reordering makes sure you always have what you need in stock. This cuts down on the work needed for manual reordering.

Improved Accuracy

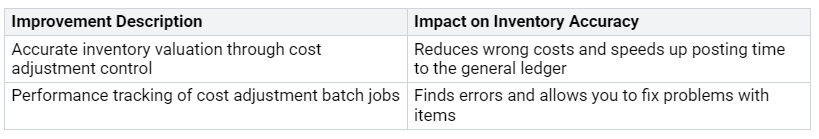

Inventory automation greatly improves accuracy in your work. With Business Central, you can get accurate inventory values through cost adjustment control. This helps reduce wrong costs and speeds up posting time to the general ledger. Tracking performance of cost adjustment batch jobs finds errors and allows you to fix problems with items.

Also, automated inventory management makes customers happier. You can ensure products are available, reduce stockouts, and give accurate delivery estimates. This leads to better order fulfillment and improves the overall customer experience.

By using inventory automation, you can keep stock levels right, save money, and improve accuracy. These benefits lead to better operations and happier customers.

Planning for Supply Chain Resilience

In today’s busy business world, planning for supply chain resilience is very important. Automated planning tools in Business Central help you respond to changes and problems. These tools keep things running smoothly and help you adjust quickly to what the market needs.

Master Planning Engine

The Master Planning Engine in Business Central is key for better supply chain resilience. It uses smart AI to help you make decisions. Here are some main benefits:

It improves inventory management and warehouse work.

The engine checks supplier performance and gives useful insights.

The Planning Optimization feature greatly boosts your planning skills. It replaces the old in-memory master planning engine with a cloud-based Azure service. This change leads to faster and more reliable planning results. You can expect:

Better planning optimization that supports new methods like Demand Driven MRP (DDMRP).

Quicker planning runs, even during business hours, so you can adjust fast to changes in demand and supply.

By using these features, you can make sure your supply chain stays flexible and ready for disruptions.

Exception Handling

Exception handling in Business Central is another important part of keeping the supply chain responsive. The system uses the TryFunction to handle errors smoothly. This ability stops disruptions in execution, which is key for efficient supply chain work. Here’s how it helps:

It makes user experiences better by reducing interruptions.

It allows for quick spotting of issues, leading to timely fixes.

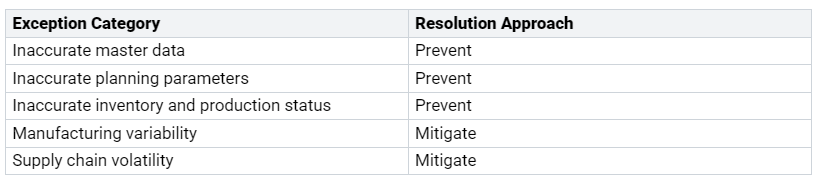

Common exceptions in supply chain planning include wrong master data and planning settings. Here’s how you can fix these problems:

By fixing these exceptions early, you can make your supply chain stronger and keep operations running smoothly.

Automated inventory replenishment in Business Central changes how you handle stock. You get real-time updates, better demand predictions, and easier ordering steps. These features help you keep the right amount of stock, lower costs, and make customers happier.

Think about these benefits:

Smart tracking of stock levels makes sure you never run out of important items.

Purchase suggestions based on forecasts help you order the right amounts.

Automated cycle counting keeps things accurate without stopping work.

By using these tools, you can make your inventory management better and improve how your business runs. Check out what Business Central can do to fully use inventory automation.

FAQ

What is automated inventory replenishment?

Automated inventory replenishment uses technology to manage stock. It helps you reorder items automatically based on what you expect to sell. This process cuts down on manual work and keeps your inventory levels just right.

How does Business Central support inventory management?

Business Central has features like demand forecasting and reorder point calculation. These tools help you make smart choices about how much stock to keep. They also automate ordering, which makes your operations run smoother.

Can I customize replenishment settings in Business Central?

Yes, you can change replenishment settings in Business Central. You can create templates, work plans, and inventory rules. This lets you adjust the system to fit your business needs.

What are the benefits of using an ERP system for inventory management?

An ERP system makes inventory management easier by connecting different business tasks. It gives you real-time data, boosts accuracy, and helps with decision-making. This leads to saving money and happier customers.

How can I monitor my inventory levels effectively?

You can check inventory levels using Business Central’s real-time features. The system sends alerts for low stock and too much stock. This helps you keep the right amount of inventory and meet customer needs.