In today’s tough manufacturing world, you need a solution that improves your processes and increases efficiency. Business Central has strong inventory management tools. These tools let you track items in real-time and set automatic reorder points. This helps you keep the right amount of stock and lower carrying costs.

Also, Business Central connects all your business parts smoothly. It gives you real-time visibility and makes operations better. This connection with Microsoft apps like Office 365 and Power BI makes workflows easier. By using Business Central Manufacturing, you can change your operations and help your business grow.

Key Takeaways

Business Central makes manufacturing better by combining inventory management and production planning in one place.

Tracking stock in real-time and automatic reordering help keep the right amount of stock. This lowers costs and stops running out of items.

Demand forecasting tools in Business Central help plan production accurately. This way, you can meet customer needs without making too much.

Quality control features check for compliance automatically. This helps keep product standards high and get ready for audits easily.

The flexible design of Business Central lets businesses start with basic features. They can add more as they grow, which saves money.

Business Central Overview

Microsoft Dynamics 365 Business Central is a strong cloud-based ERP tool. It is made for small and medium-sized businesses. It helps make many business tasks easier. This includes manufacturing, finance, and supply chain management. You can manage everything from one place. This makes things work better and cuts down on mistakes.

In manufacturing, Business Central is very important. It has many features that improve production. You can track production orders and manage bills of materials (BOMs). You can also check inventory levels in real-time. This clear view helps you make smart choices and react fast to changes in demand.

The real power of Business Central is its connection to the Microsoft ecosystem. It gives you one platform that links all parts of the business.

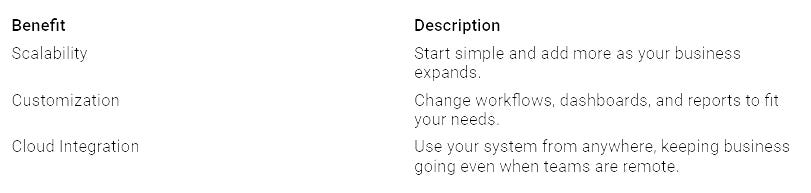

Here are some key benefits of using Business Central for manufacturing:

Real-time dashboards with Power BI for product profits and inventory trends.

Easy integration with Microsoft tools like Teams, Excel, and Outlook for better teamwork.

Full visibility of manufacturing operations from sales forecasts to finished goods.

Business Central’s flexible design lets you start with basic features. You can add more as your business grows. This means you only pay for what you need, making it a smart choice.

By using Business Central, you give your manufacturing operations the tools for success. You boost teamwork, increase productivity, and help your business grow.

Streamlining Production with Business Central

Business Central is very important for making production better. It helps solve problems with different systems and bad scheduling. By bringing everything together, you can get rid of the mess from using many tools. For example, Aegis Softtech used Business Central to combine different systems into one cloud-based ERP solution. This change helped them automate tasks and get real-time information. This way, they can respond quickly to what customers need.

Production Orders & BOMs

Production orders are very important in manufacturing. They have key details about products that need to be made and the materials needed. You can make production orders by hand or create them from different planning pages. This choice helps you manage orders well.

Bills of Materials (BOMs) list the parts that go into a product. You must check the BOM before using it. When you add a product to a production order, the BOM automatically fills in the order parts. This connection makes sure you have all the materials needed for production.

Here are some key benefits of using production orders and BOMs in Business Central:

Improved Planning: You can plan future production and control current tasks well.

Enhanced Tracking: Easily track finished products to meet customer needs.

Streamlined Processes: Automate making production orders to cut down on mistakes.

Capacity & Resource Planning

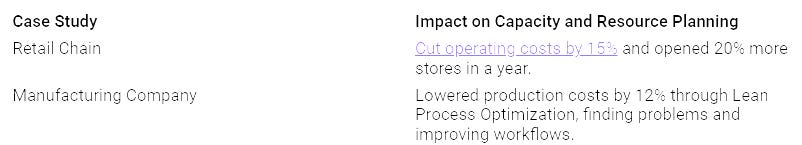

Good capacity and resource planning are key for better production. Business Central gives real-time information that helps with scheduling. You can manage and improve production schedules better, leading to big efficiency gains. Companies using Business Central have seen improvements of 20-30% by syncing operations and automating quality checks.

The system shows clear information about production costs. This helps in making smart choices about pricing and how much to produce. You can look at what parts you need and what is in stock. This helps you find gaps between what you need and what you have. Managing materials well makes sure you have what you need and stops production delays.

Here’s a summary of the impact of Business Central on capacity and resource planning:

With Business Central, you get the tools to make production processes better. You increase visibility, improve scheduling, and keep your manufacturing operations running smoothly.

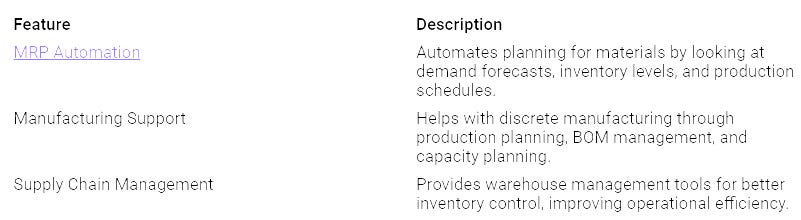

Manufacturing Resource Planning (MRP)

Manufacturing Resource Planning (MRP) is very important for matching your production plans with what customers want. When you use MRP in Business Central, you can make a clear manufacturing schedule. This schedule is based on expected demand, how much inventory you have, and what materials you need. The system looks at how many finished items you need, the bill of materials for each product, and your target inventory levels. This way, your production can quickly respond to what customers want.

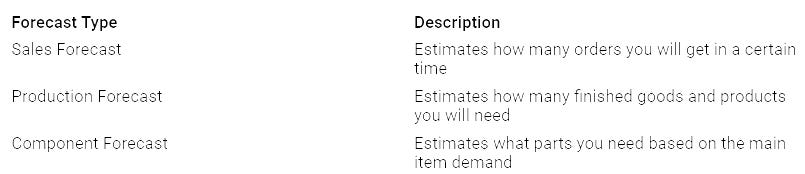

Demand Forecasting

Good demand forecasting is key for successful manufacturing. Business Central has different ways to forecast demand. This helps you get accurate predictions for what you need to produce. Here are some important types of forecasts you can use:

These forecasting methods help you know what customers will want and change your production plans. With Business Central’s built-in demand forecasting, you can automatically figure out what materials you need, when you need them, and how much to get. This automation helps prevent running out of stock and makes sure you have the right materials ready when you need them.

Inventory Management

Inventory management is another important part of MRP. Business Central’s inventory management system helps reduce stockouts and extra inventory in your manufacturing. Here are some key features that improve your inventory management:

Real-time Inventory Tracking: Gives you accurate, up-to-date information on inventory levels, helping you track stock movements and cut down on mistakes.

Automated Reordering: Automatically places orders to stop stockouts, making sure you always have what you need.

Stock Level Optimization: Helps keep the right amount of stock to meet demand without overstocking.

By connecting MRP with finance and supply chain management, Business Central boosts your operational efficiency. The table below shows the integration features:

With these tools, you can make your manufacturing processes smoother, improve inventory management, and keep your operations running well. By matching your production with demand forecasting and managing your inventory effectively, you set your business up for success.

Quality Control in Manufacturing

Quality control is very important in manufacturing. It makes sure your products meet the right standards and rules. Following these rules is key to keeping customer trust and avoiding expensive fines. Business Central helps you manage these rules well. It makes your quality control processes easier and prepares you for audits.

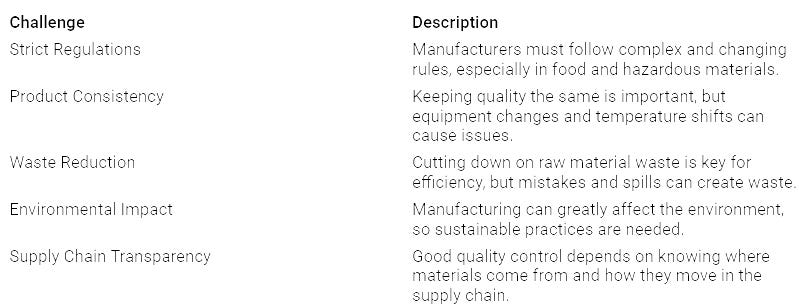

Here are some common quality control problems you might see in manufacturing:

Business Central automates checks and makes sure you follow the rules. It gives real-time quality checks to lower defects. Non-compliant inventory is automatically stopped from production, ensuring only quality products reach your customers.

Compliance and Reporting

Business Central helps you follow industry-specific quality rules. It has features that improve your quality control processes. For example, it keeps complete audit trails and ensures reliable digital records with electronic signatures. This helps you meet strict regulatory needs, like those from the FDA and EU.

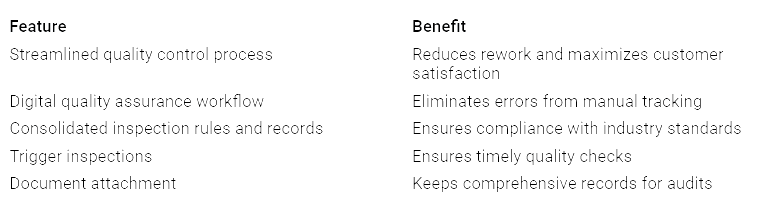

Here are some key features that help with compliance:

Continuous Improvement

Continuous improvement is key for better efficiency in manufacturing. Business Central helps with this by giving tools for reviewing incidents and reporting. You can do weekly reviews of incidents that affect customers to find important lessons. This process helps you adapt and improve your manufacturing operations.

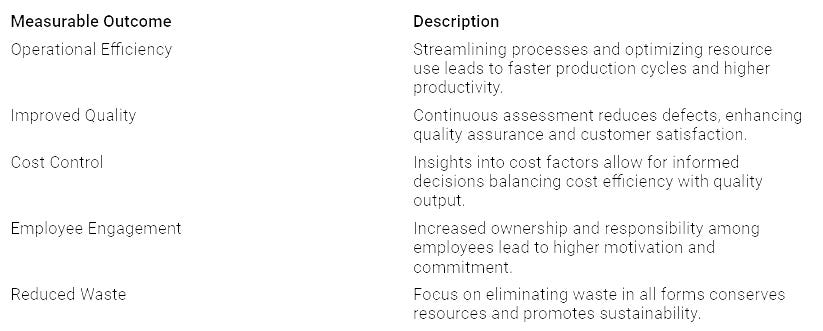

The measurable results of continuous improvement efforts supported by Business Central include:

By using Business Central’s features, you can ensure compliance, improve quality control, and create a culture of continuous improvement in your manufacturing operations.

Case Study: Successful Implementation

A medium-sized electronics maker recently started using Business Central to improve its work. This company had problems with different systems and slow processes. After using Business Central, they saw great results.

They boosted production efficiency by 20%.

They cut inventory costs by 15%.

They made financial processes better and improved their supply chain.

These changes helped them set better product prices and made customers happier. The smooth connection of Business Central with their current systems allowed for real-time inventory tracking. This clear view helped the company react quickly to market needs.

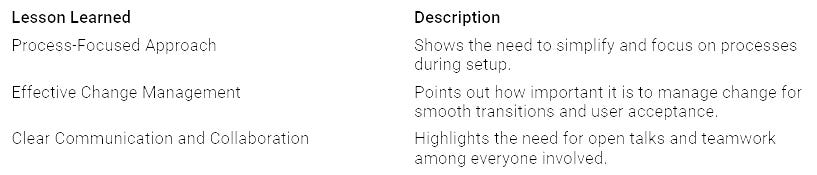

During the setup process, the company learned some important lessons:

These lessons helped the company handle challenges and get the most out of Business Central. By focusing on improvement and good integration, they changed their operations. This case study shows how Business Central can boost performance and improve overall efficiency in manufacturing.

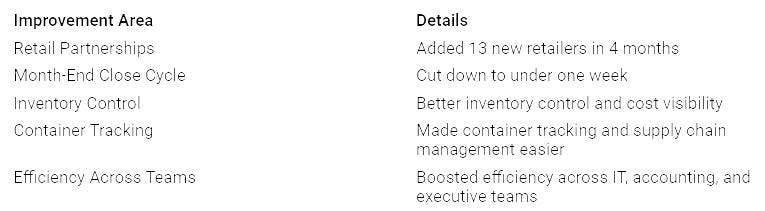

Business Central has many benefits for your manufacturing work. It helps you make processes easier, see things better, and work more efficiently. Many companies see big changes after using Business Central. For instance, they added 13 new retailers in just four months. They also cut their month-end closing time to less than one week.

Here’s a summary of the improvements you can expect:

Check out what Business Central can do for you today. You can change your manufacturing operations and help your business grow.

FAQ

What is Business Central Manufacturing?

Business Central Manufacturing is a tool that helps make your manufacturing easier. It combines production orders, inventory management, and resource planning all in one place. This helps you work better and react fast to changes in the market.

How does Business Central help with demand forecasting?

Business Central looks at past data and trends to guess future demand. This feature helps you plan your production schedules based on what customers want. Good demand forecasting helps you avoid running out of stock and keeps your inventory levels just right.

Can I customize Business Central for my manufacturing needs?

Yes, you can change Business Central to fit your manufacturing needs. You can adjust workflows, dashboards, and reports. This flexibility makes sure the system works well for your specific operations as your business grows.

Is Business Central suitable for small and medium-sized manufacturers?

Yes! Business Central is made for small and medium-sized businesses. It offers big company features at a size that works for you. This makes it a great choice for manufacturers who want to improve their operations without making things too complicated.

How does Business Central support quality control?

Business Central helps with quality control by using automated checks and tracking compliance. It helps you keep product standards and get ready for audits. This ensures your manufacturing processes follow industry rules and meet customer expectations.