Purchase order processing means the steps to create and manage purchase orders. This process is very important for business operations. A good purchase order system helps you control costs, improve workflows, and follow rules.

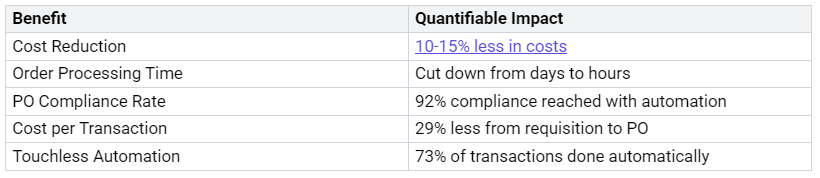

Think about these clear benefits of using a good purchase order system:

With these benefits, you can improve your buying processes and make better choices.

Key Takeaways

Make your purchase order steps the same. This helps keep things consistent and lowers mistakes.

Teach your workers often. This helps them understand rules better and work faster.

Use automation to make tasks quicker. This cuts down on errors and helps you see your buying activities better.

Keep communication clear during the purchase order process. This helps prevent delays and confusion.

Check important numbers to see how well your purchase order process works. Change things if needed.

Understanding Purchase Order Processing

Define the concept and its significance in business.

Purchase order processing means the steps to create and manage purchase orders (POs). This process is very important for businesses. It helps you control spending, manage supplier relationships, and follow rules. Good purchase order management can make your business run better and earn more money. Studies show that companies with strong purchase order management can improve efficiency by 20% and governance by 31%. These changes lead to better financial reports, which are important for checking your company’s money situation. Accurate POs create debts on balance sheets and affect cash flow statements. This ensures your financial documents show the real state of your business.

Discuss the role of compliance and efficiency.

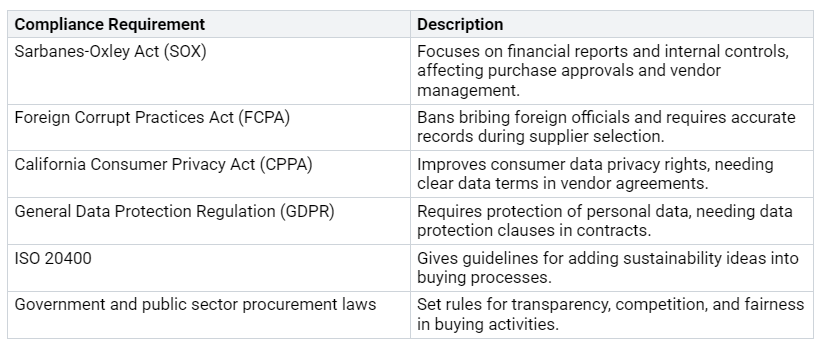

Compliance is very important in the purchase order process, especially in regulated industries. You must follow different rules to avoid legal and financial problems. Here are some key compliance requirements:

To ensure compliance, set up strong control systems. Approve all purchase orders by authorized people and use only approved vendors. Keep detailed records of all purchase orders and approvals for audits. These practices help you reduce risks and improve the efficiency of your buying process.

Purchase Order Process Steps

Creating a Purchase Order

The first step in the purchase order process is to create a purchase order (PO). This step is very important. It sets up everything that comes next. Here’s how to create a purchase order step by step:

Create a Purchase Requisition: First, find out what goods or services you need. Write this down in a purchase requisition.

Get Approvals for Purchase: Send the requisition to the right people for approval.

Fill Out the Purchase Order Form: After getting approval, fill out the purchase order form. Include details like item descriptions, amounts, and prices.

Send the Purchase Order to the Supplier: Send the finished purchase order to the supplier.

Get Vendor Acknowledgment: Make sure the supplier confirms they got the purchase order.

Receive the Purchase Order: Check that the supplier has processed your order.

Integrate with Inventory Management (Optional): If needed, update your inventory system to show the new order.

This organized purchase order process helps you keep control over buying and makes sure you follow internal rules.

Approval Workflow

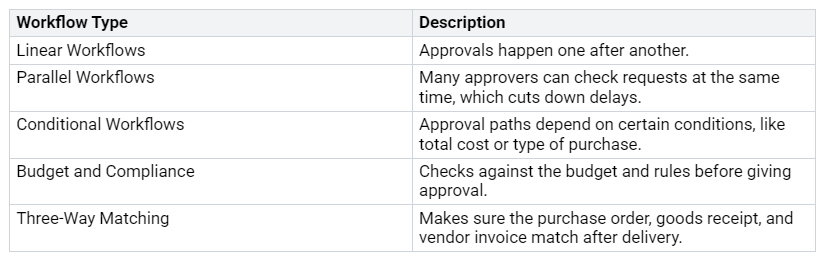

After creating the purchase order, the next step is the approval workflow. This workflow makes sure all purchase orders get the needed approvals before moving forward. Here are some common types of approval workflows:

Using a digital approval workflow can speed up and improve the accuracy of purchase order processing. Automation removes manual tasks, making things faster. Automated alerts remind approvers to act quickly, which helps avoid delays.

Order Fulfillment

Once the purchase order is approved, the next step is order fulfillment. This stage is when the supplier gets ready and ships the items you ordered. But there can be problems during this process:

To check how well your order fulfillment works, track metrics like the order fulfillment rate and fill rate. These metrics show how well operations run and how happy customers are.

Receipt of Goods

When the supplier brings the goods, you need to check the receipt against the purchase order. Follow these steps to make sure everything is correct:

Signing for Deliveries: The person receiving should sign the delivery papers and check items before signing.

Inspecting a Shipment: Make sure products meet purchase order needs, check amounts, and look for damage.

Determining Acceptance: Contact the supplier right away for any rejected items to avoid automatic acceptance.

Using tools like purchase order management software and electronic data interchange (EDI) can make this process easier, ensuring accurate tracking and records.

Invoice Matching

After you receive the goods, the next step is invoice matching. This process compares the invoice with the purchase order and the receipt of goods. Here are some best practices for good invoice matching:

Use three-way matching for expensive or complex purchases to lower mistakes.

Use automation to make the matching process easier.

Standardize data entry to cut down errors and speed up matching.

Fix any mistakes right away when you find them. Talk directly with the vendor to solve any problems quickly.

Payment Processing

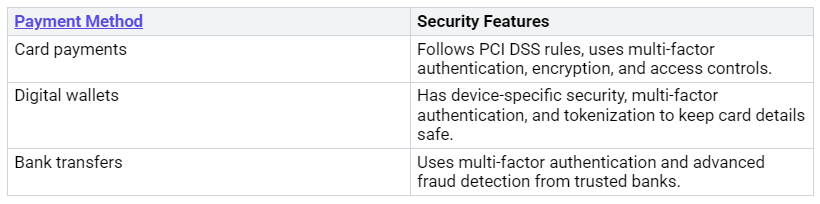

The last step in the purchase order process is payment processing. Paying on time is key for keeping good supplier relationships. Here are some safe ways to process payments:

Delays in payments can hurt vendor relationships and lead to late fees. Good communication during the purchase order process builds trust and teamwork with suppliers.

Best Practices for Purchase Order Processing

Standardization of Processes

Making your purchase order processes the same is very important. It helps with consistency and efficiency. You should clearly explain what products or services you need. This helps everyone know what to expect. Here are some important things to think about:

Make a clear and repeatable set of steps for buying.

Use standard documents, like templates for orders and contracts.

Set up clear ways to communicate and report.

By using the same purchase order templates and steps across the company, all departments will follow the same rules. This cuts down on mistakes and repeats, which means fewer corrections needed. Your teams can then focus on important tasks instead of fixing errors, making everything run better.

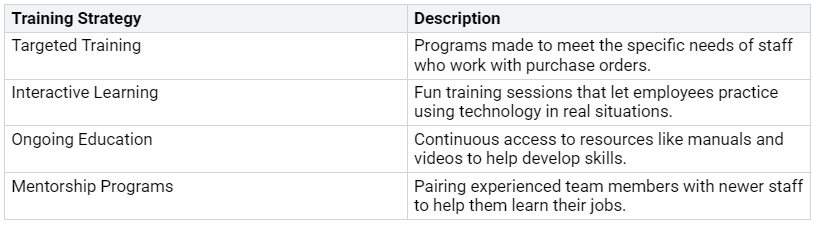

Staff Training

Training your staff is key for good purchase order processing. Ongoing training helps employees understand the rules, which is important for following them. Here are some good training ideas:

These training programs help cut down on mistakes and create a sense of responsibility among your staff. They help connect understanding the rules with actually using them, which leads to better compliance.

Leveraging Technology

Using technology can really make your purchase order processing easier. Here are some helpful technologies to think about:

Procurement software cuts down on manual mistakes and saves time.

Automation takes care of repetitive tasks like making orders and sending them for approval.

Advanced systems can work with different types of purchase orders and pull out product and supplier details without needing help.

Using purchase order automation software can also lower costs. For example, it makes things more efficient by reducing time spent on manual work. This lets your team focus on more important tasks. Plus, it helps avoid money lost from wrong orders and duplicate purchases.

Adding these best practices to your purchase order processing will improve control, compliance, and how well things run.

Common Pitfalls in the Purchase Order Process

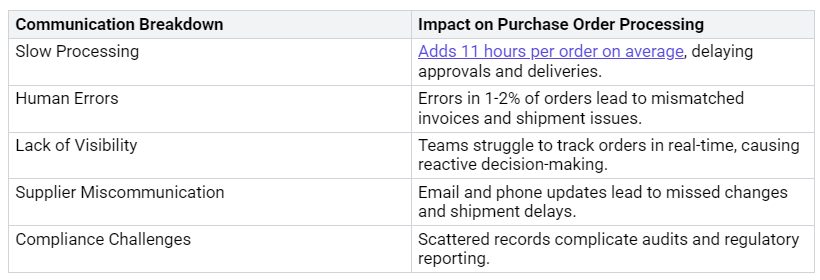

Lack of Communication

Good communication is very important in the purchase order process. When communication fails, it can cause big delays and mistakes. Here are some common problems that happen when communication breaks down:

To make communication better, think about using software for automatic notifications. This keeps suppliers updated about order statuses and reduces misunderstandings. A clear purchase order workflow helps everyone communicate better, which lowers the chances of mistakes.

Inaccurate Data Entry

Wrong data entry can really hurt your purchase order processing speed. Mistakes in data can cause wrong orders, delays, and higher costs. Here are some problems caused by inaccurate data entry:

Disruption of business operations.

Compromised decision-making.

Damage to supplier relationships.

Gartner says that bad data costs companies about $12.9 million each year. This shows how much money is wasted because of lost chances and resources. Using data validation methods can help stop these mistakes. For example, using rules to check data patterns can make sure the information is correct.

Delayed Approvals

Slow approvals can create confusion and hurt relationships with suppliers. Making purchase orders by hand often raises the chance of mistakes. These mistakes can lead to wrong orders and rejected invoices, wasting time and resources. Here are some common reasons for delayed approvals:

Slow approvals can also make procurement decisions harder, increasing the time needed to finalize orders. Making your approval process faster through automation can greatly improve efficiency and strengthen supplier relationships.

Benefits of Automation in Purchase Order Processing

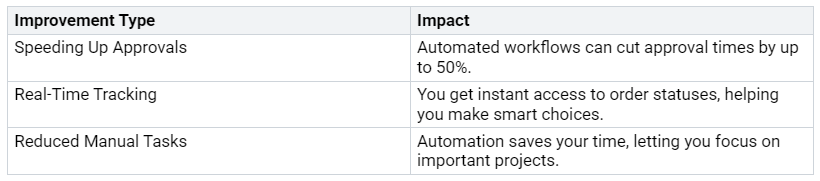

Increased Efficiency

Using automation in purchase order processing can really help you work faster. It makes workflows smoother, which cuts down on mistakes and speeds up approvals. For example, automation can change the time for purchase orders from days to just hours. This lets you focus on saving money and improving buying processes. Here’s how automation helps you be more efficient:

Reduced Errors

Using automated purchase order systems can greatly lower processing mistakes. Many organizations see a 90% reduction in processing errors after they start using these systems. This improvement happens for a few reasons:

Automation removes the need for manual data entry, which often has errors.

Standard templates keep all purchase orders consistent.

Real-time checks help find mistakes before they become bigger problems.

By cutting down on errors, you save time and also build better relationships with suppliers while staying compliant.

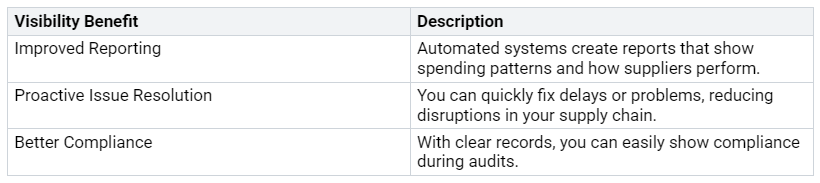

Enhanced Visibility

Automation gives you better visibility into your purchase order process. You can track orders in real-time, which helps you see progress and spot problems early. This visibility helps you make better decisions and communicate well with suppliers. Here are some benefits of having better visibility:

Conclusion

In this guide, you learned how important purchase order processing is for businesses. You saw how a good purchase order system can help with control, compliance, and efficiency. By following the steps given, you can make a smoother process that cuts down on mistakes and helps your relationships with suppliers.

You also looked at best practices for purchase order processing. Making your processes the same, training your staff, and using technology can really improve your efficiency. It’s important to avoid common problems like poor communication and wrong data entry to keep things running smoothly.

Automation was a big idea in this guide. It not only makes things faster but also lowers mistakes and gives you better visibility into your buying activities. By using automation, you can turn your purchase order process into a strong advantage for your business.

In the end, understanding and improving your purchase order process leads to better results for your business. You can save money, improve compliance, and build stronger partnerships with suppliers. Use the ideas from this guide in your work. Your efforts will pay off over time, making your purchasing processes more effective and dependable.

In this guide, you looked at how important purchase order processing is for your business. You found out that good management can save money, improve compliance, and build better relationships with suppliers.

Here are the main points:

Standardization: Make your processes the same for consistency.

Training: Teach your staff what they need to know.

Automation: Use technology to work faster and cut down mistakes.

By improving your purchase order process, you set your business up for success. Use these strategies to get better results and help your business grow. 🌟

FAQ

What is a purchase order?

A purchase order (PO) is a paper that buyers give to suppliers. It lists the items or services needed, how many, and the prices agreed upon. POs help keep track of orders and make sure both sides know the details of the deal.

Why is purchase order processing important?

Purchase order processing is very important for controlling costs, following rules, and keeping good relationships with suppliers. It makes buying easier, cuts down on mistakes, and helps you see where money is going, which leads to better choices.

How can I improve my purchase order process?

You can make your purchase order process better by making steps the same, training your staff, and using technology. Automation can also help things run smoother and lower mistakes, making your buying more efficient.

What are common challenges in purchase order processing?

Common problems include poor communication, wrong data entry, and slow approvals. These issues can cause mistakes, higher costs, and bad relationships with suppliers.

How does automation benefit purchase order processing?

Automation makes things faster by speeding up workflows, cutting down on manual work, and lowering mistakes. It gives you real-time updates on orders, helping you make smart choices and stay compliant.