In today’s fast-moving market, you see constant changes. These changes need quick adjustments. The global supply chain is changing too. Disruptions like shortages of raw materials happen often. Consumer behaviors are also changing. This unpredictability means using real-time supply chain data, powered by Microsoft Fabric, is a must. It is important to stay competitive. Companies need to accept digital changes to connect their processes smoothly. As we get closer to 2025, the need to improve efficiency and flexibility will grow.

Key Takeaways

Use real-time data to make your supply chain faster. Microsoft Fabric gives you the tools to react quickly to market changes.

Connect your data systems to remove barriers. This helps everyone see and make better decisions, which leads to more efficiency.

Use predictive analytics for better inventory control. Good forecasts help avoid having too much or too little stock, keeping customers happy.

Use automation to make processes easier. Automating tasks cuts down on mistakes and increases productivity in order fulfillment and inventory control.

Take a proactive approach to managing your supply chain. Focus on predicting problems and using technology to stay ahead in a fast-moving market.

The Problem: Black Box Supply Chains

In regular supply chains, you often deal with broken data. This happens when different systems work alone. You might see several types of broken data:

Operational Fragmentation: Unlinked business steps cause problems and confusion.

Geographic Fragmentation: Spread-out supply chains lead to longer wait times and higher costs.

Supplier Fragmentation: Many suppliers make managing relationships harder and raise costs.

Technological Fragmentation: Separate systems block data sharing and visibility, hurting decisions.

Organizational Fragmentation: Different management of production parts makes teamwork tough.

These problems can have big effects on your work. For example, you could face:

Higher Costs and Lower Efficiency: Broken data can raise shipping costs and slow down work.

Quality Control Issues: Less oversight can lower product quality in broken supply chains.

Longer Wait Times and Delays: Working across broken systems can cause big delays.

Visibility gaps make these problems worse. Without real-time information, you find it hard to share details. This lack of visibility can lead to:

Wrong delivery updates that hurt customer trust and happiness.

Higher shipping costs because of unclear shipment status, needing faster shipping.

Poor use of resources and trouble adjusting to surprises, leading to unhappy customers.

As you deal with these issues, remember that real visibility is key for good supply chain management. Without it, you might fall behind in a tough market.

Why Traditional Systems Fail

Traditional supply chain management often has problems with data silos. These silos happen when departments work alone. This leads to broken information. When you don’t have combined data, you face many challenges:

Inadequate Shared Network: Departments make conflicting choices, wasting and ignoring data.

Poor Decision Making: Not sharing data makes logistic companies miss chances and money, causing bad choices.

Disrupt Functionalities: Broken information disrupts supply visibility and raises risks of missing deadlines.

Wastage of Resources: Fragmented information causes repeated data downloads, raising storage costs.

Difficulties in AI Solutions: AI needs combined data; scattered data slows down algorithm performance.

When departments use separate data sets, their strategies often clash. For example, sales and marketing teams might miss chances to earn money because they don’t work well together. You may also find old information that makes decision-making hard. Time spent looking for data could be used for more important tasks. Bottlenecks in teamwork can lead to focusing on personal goals instead of company needs.

Another big problem is the ‘telephone game‘ effect in communication. This happens when messages get mixed up as they go through different levels of the organization. Misunderstandings can cause confusion and poor execution at work. Employees often feel unsure about what leaders want, leading to inefficiencies.

The phenomenon can cause significant operational issues, as seen in the example of the Space Shuttle Columbia disaster, where poor communication led to fatal consequences.

To fix these problems, you must focus on data integration and clear communication. Only then can you improve your supply chain management and keep operations running smoothly.

Microsoft Fabric + Dynamics 365 Solution

Microsoft Fabric acts like the brain for seeing your supply chain in real-time. It brings together data from different places. This creates one platform that helps everyone work together better. With this setup, you can watch your supply chain operations closely. This leads to clearer information and better efficiency.

Real-time Alerts and Automation

With Microsoft Fabric, you get real-time alerts. These alerts keep you updated on important supply chain events. You can track shipments, inventory levels, and production schedules as they happen. Quick notifications about problems help you respond fast. This reduces delays and costly mistakes. Here are some key benefits of real-time alerts:

Enhanced Monitoring: Spot issues in your supply chain quickly.

Improved Transparency: Work well with others using a shared data platform.

Optimization and Efficiency: Find areas to improve, saving costs and boosting performance.

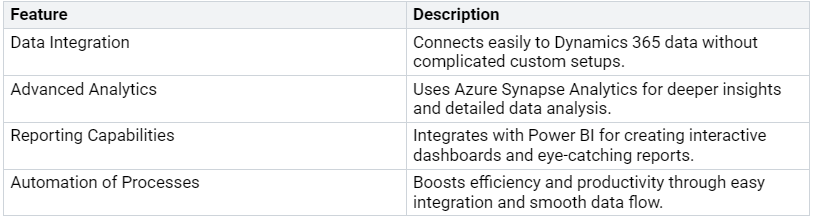

Automation is very important for making your supply chain processes easier. By automating key tasks, you lower manual errors and boost efficiency in order fulfillment and inventory management. Microsoft Fabric works well with Dynamics 365 for smooth data flow. This is crucial for making timely decisions.

Predictive Insights for Decision-Making

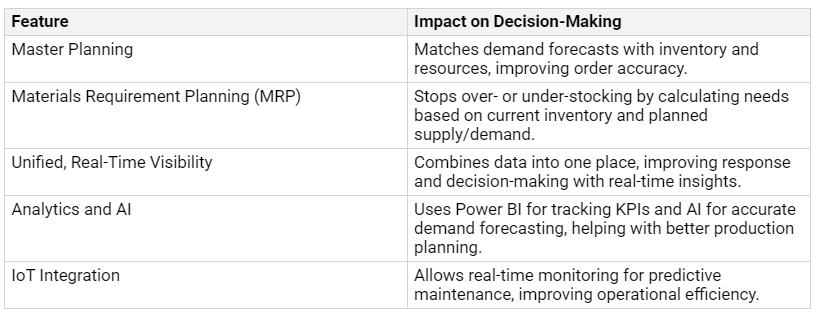

Predictive analytics from Microsoft Fabric and Dynamics 365 greatly improve your decision-making. These tools give you real-time insights. They help you match demand forecasts with inventory and resources. This matching improves order accuracy and stops over- or under-stocking. Here are some features that help with better decision-making:

By using these predictive insights, you can make smart decisions that boost your supply chain agility. A global electronics maker improved its supply chain visibility by 92% and cut excess inventory by 45% after using Microsoft Fabric. This success came from building a unified data platform that connected separate systems, allowing for real-time visibility and proactive management.

How It Works: Real-time Visibility

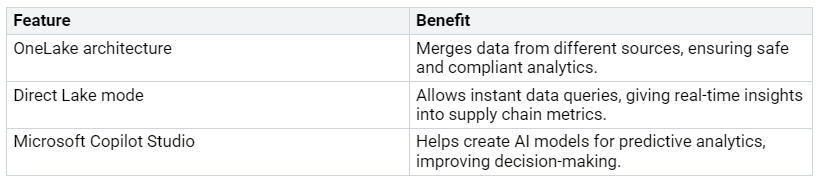

Microsoft Fabric changes how you manage your supply chain. It combines real-time data into a living analytics layer. This helps you access and analyze information from different sources easily. Here’s how it works:

Real-time analytics: Microsoft Fabric is made for streaming data. It gives you the latest insights to help you make quick decisions.

Unified data models: The platform merges shop-floor data with company metrics. This way, you can see everything about your supply chain at once.

Simplified data access: You can get data easily using tools like Power BI, Excel, and Teams. This makes sure you have the information you need right away.

By combining these metrics, Microsoft Fabric removes data silos. You can share datasets and insights instantly, creating one source of truth for your organization. This change improves teamwork between developers and users, leading to faster decision-making.

Immediate alerts are very important for keeping real-time visibility. With Microsoft Fabric, you get notifications about key supply chain events as they happen. This ability lets you:

Identify issues quickly: Real-time tracking of goods and materials improves visibility and transparency in the supply chain. You can find bottlenecks and problems quickly.

Improve demand forecasting: Accurate and real-time data helps make sure production meets customer needs. This prevents extra inventory and cuts costs.

Enhance vendor performance tracking: Constantly checking vendor performance helps you see how reliable and efficient they are. You can make smart choices about suppliers based on real-time data.

The benefits of immediate alerts and ongoing vendor performance tracking are huge. You can react to changes in demand or supply chain problems right away. This agility not only boosts your operational efficiency but also increases customer satisfaction.

Use Cases and ROI

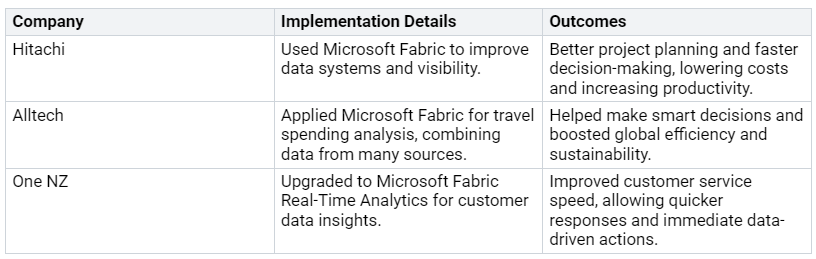

Many companies have improved their supply chain speed by using Microsoft Fabric and Dynamics 365 SCM. Here are some examples:

These companies show how using Microsoft Fabric can greatly enhance supply chain work.

You can also see great returns on your investment. Companies that use Microsoft Fabric can get an average return on investment (ROI) of 379% over three years. The time to pay back this investment is less than six months. The Forrester Total Economic Impact study shows big cost savings and business benefits from using Microsoft Fabric.

After using Microsoft Fabric and Dynamics 365 SCM, key performance indicators (KPIs) show amazing changes:

You will see real-time insights into inventory changes, better responses to supply chain shifts, and improved decision-making through predictive analytics. These results show the powerful impact of Microsoft Fabric and Dynamics 365 SCM in today’s supply chain management.

The Future of Supply Chains

The future of supply chains is changing from waiting for problems to acting before they happen. You can’t just sit back and wait for issues to show up. You need to see challenges coming and act quickly. Good leadership is very important for this change. Leaders should spend time and resources on proactive tasks. This helps stop companies from just reacting to problems.

To make this change, think about these important strategies:

Adoption of digital and data-driven solutions: Use technology that improves visibility and efficiency.

Implementation of advanced technologies: Use tools like RFID tracking and IoT devices to watch your supply chain in real-time.

Fostering a culture of change: Build an environment that supports new ideas and innovation.

As you shift to a proactive way of working, the idea of a self-learning supply chain becomes very important. This idea uses new technology to create systems that learn and get better over time. Here are some ways this idea is being put into action:

AI and robotics: These technologies focus on reliable production instead of just low wages.

Regular updates to machine learning models: These updates keep things accurate and help businesses adjust to sudden changes.

Automation: AI and machine learning make logistics planning easier and more efficient.

The expected benefits of using self-learning supply chain systems in the next five years are impressive:

By accepting these changes, you can set your supply chain up for success in a fast-changing world. Using tools like Microsoft Fabric and Dynamics 365 will help you face this future with confidence.

You can change how your supply chain works by using Microsoft Fabric and Dynamics 365. These tools give you real-time information and smart predictions. You will shift from reacting to problems to planning ahead. Use digital solutions to improve efficiency and lower costs. The future of supply chains is about being quick and flexible. By using these technologies, you prepare your business for success in a fast-changing market.

Remember, real visibility links every signal into one system. Begin your journey today!

FAQ

What is Microsoft Fabric?

Microsoft Fabric is a data platform that connects different data sources. It gives you real-time views of supply chain operations. This helps you make better decisions and work more efficiently.

How does Dynamics 365 SCM enhance supply chain agility?

Dynamics 365 SCM makes processes smoother and automates tasks. It helps you react quickly to changes, manage inventory better, and work well with other departments.

Can Microsoft Fabric help with demand forecasting?

Yes! Microsoft Fabric uses smart analytics to match demand forecasts with inventory. This helps you avoid having too much or too little stock, making orders more accurate.

What are the benefits of real-time alerts?

Real-time alerts keep you updated on important supply chain events. They help you spot problems quickly, cut down delays, and improve overall efficiency.

How can I start using Microsoft Fabric and Dynamics 365 SCM?

Start by looking at your current supply chain processes. Find key data sources and connect them with Microsoft Fabric and Dynamics 365 SCM to gain real-time insights and boost agility.